ApplicationsTypical use cases for our products and services

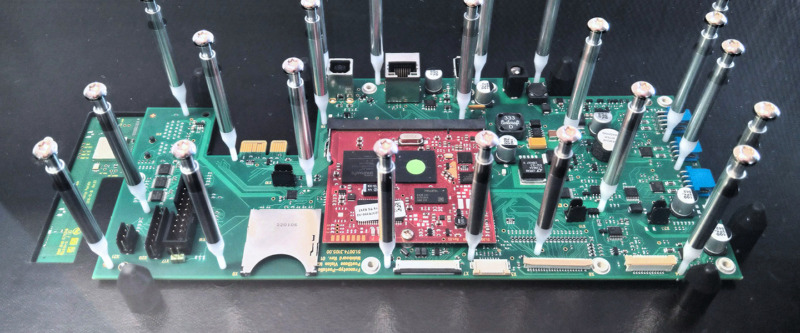

During in-circuit testing, a series of physical tests are performed (e. g. resistance measurement), which can identify structural defects during manufacturing.

During industrial functional testing, devices under test are examined for whether they meet pre-defined specifications required for their future application.

Automated optical inspections allow for the monitoring of labelling processes as well as checking for production faults and dimensional accuracy.

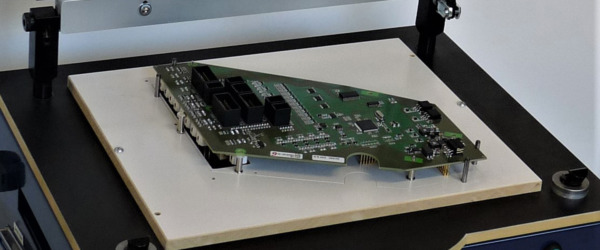

During a printed circuit board test (PCB test), PCBs are checked for production faults and correct functioning.

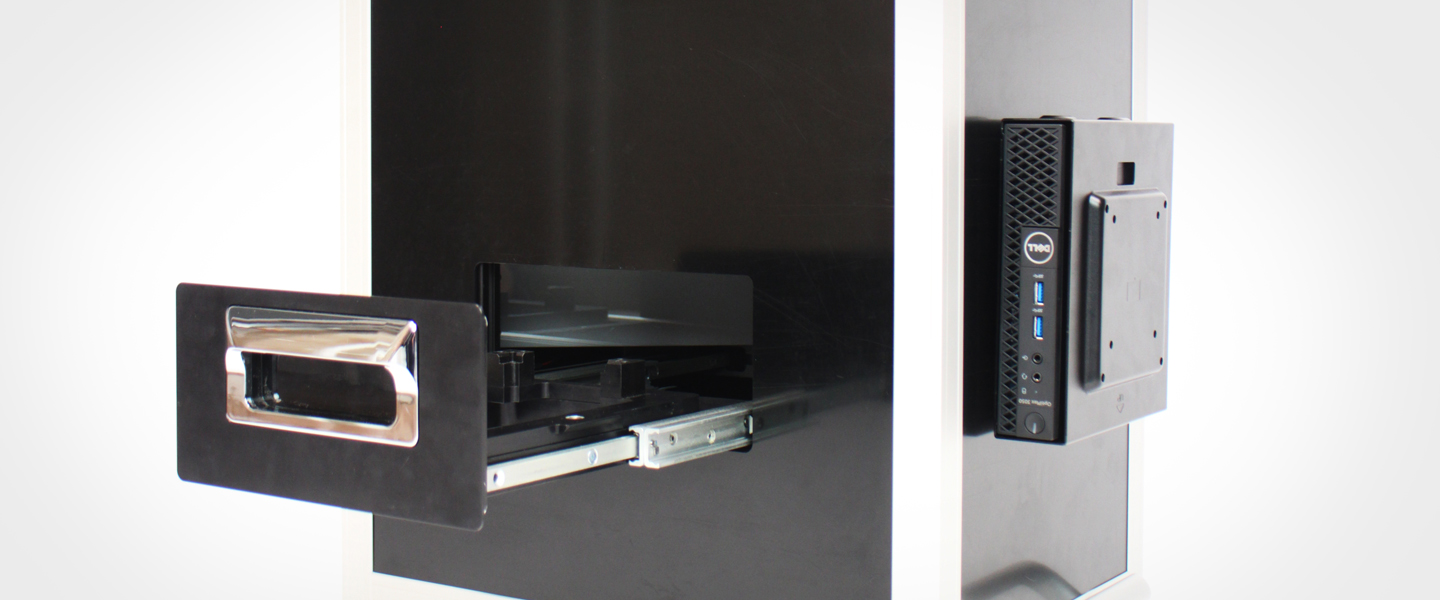

The term end of line test (EOL test) refers to quality control tasks which are executed at the end of a production line.

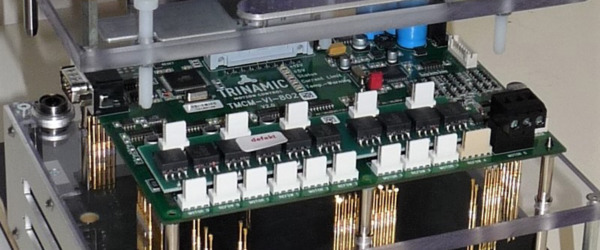

In Hardware-in-the-Loop testing, electronic controls or mechatronic components (devices under test, DUTs) are evaluated by a realistic real-time simulation model.

Test benches (also test rigs) are quality assurance stations in manufacturing or product design, at which components or products are replicably inspected.