Functional Testing (FCT)

of printed circuit boards (PCBs) or electronic devices

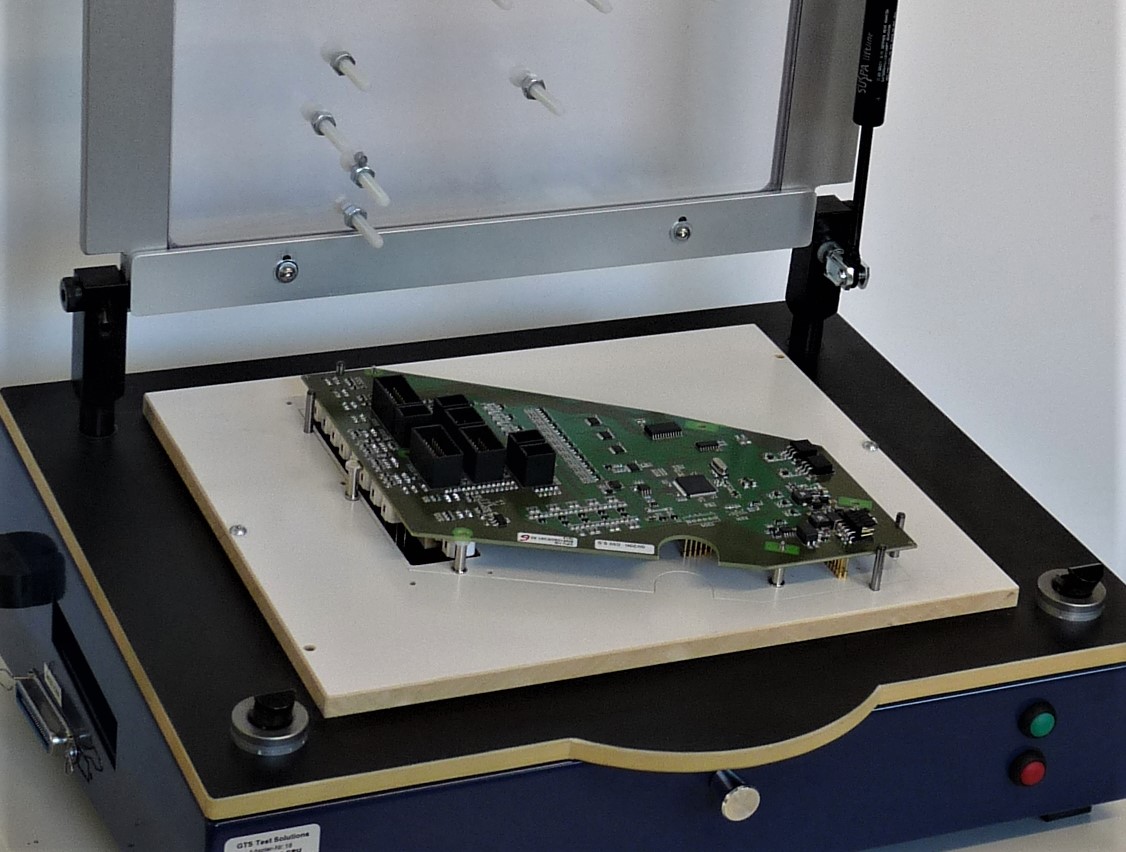

Printed circuit board (PCB) ready for functional testing

What is functional testing?

Functional testing (FCT) is a quality assurance step in manufacturing. Devices under test (DUTs) are examined for whether they meet pre-defined specifications required for their future application. Besides tests concerning the core product functionality, it is best practice to test the reactions of a DUT to undesirable states (e. g. switching off on overvoltage). Functional tests are usually performed at the end of the production line of a functional unit.

How are functional tests conducted?

During functional testing a DUT is examined for its reaction to different external influences which are relevant for its intended application. It only passes the test if the reactions meet the desired behaviour. Typical influences are:

- Changes at the electrical inputs (e. g. voltage dips or interruptions)

- Digital input signals (e. g. communication messages through KNX, DALI, CAN, I2C, Flexray etc.)

- (Simulated) operation of user interfaces (e. g. buttons, rotary controls)

- Interaction with sensors (e. g. NFC)

- Environmental conditions (e. g. high or low temperatures)

Differentiation from related testing methods

Functional testing needs to be distinguished from other electrical tests that check for production faults by examining physical features rather than functional reactions (e. g. detection of faulty soldering by checking electrical resistances):

- In-circuit tests (ICT): Inspection of assembled PCBs, contacting with specialised needle bed adapters, many test points simultaneously

- Flying probe test (PBT): Inspection of assembled PCBs, contacting with universal flying probe testers, few test points sequentially

What is required for functional testing?

For functional testing in industrial environments, the following hardware and software is required:

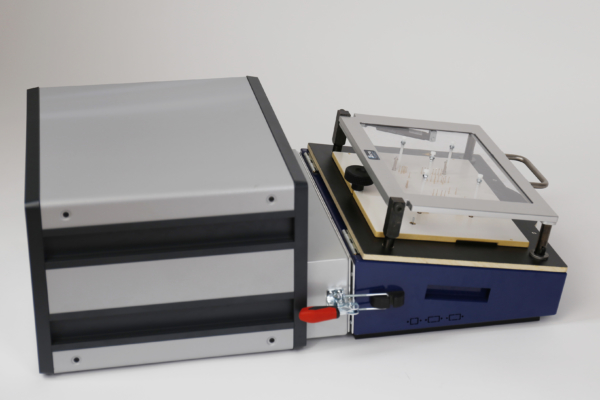

- A test control unit (FCT tester), which handles the DUTs exposure to external influences and measures its reactions precisely and in real time (e. g. our Guardian FCT tester)

- A means of connection between the control unit and the DUT (test adapter), which allows time-efficient or even automated contacting of the DUT (e. g. test adapters by GTS Test Solutions)

- Real-time inspection software for programming and executing test sequences (e. g. WinGuard)

- Required sensors (e. g. colour sensors) and systems for the generation of environmental conditions (e. g. climatic chambers)

Guardian FCT tester with connected test adapter of the series PA450

Do you need help with functional testing?

Our competent and creative team gladly provides help and advice. Besides our in-house software and hardware for functional testing, we offer integration services and turnkey test benches. We are looking forward to your contact enquiry!