Why ESD protection?

You know electrostatic discharges from your daily live: probably you have already got an electric shock touching a doorhandle after walking over a carpet. For you to perceive this electrostatic discharge, your body must have been charged with at least 3,000 volts.

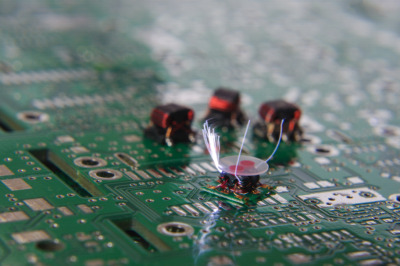

In industrial settings the topic is very concerning: Due to their ongoing miniaturisation, electronic components are more and more prone to electrostatic discharges. Today the average sensitivity of components is estimated to be around 35 volts. The comparison of this value with the previous paragraph makes one realise, how easily components can be damaged by uncontrolled electrostatic discharges. Additionally, damages caused by them are mostly invisible. Consequently, they are often detected very late in or even after the production process leading to high costs of correction.

That is why charges need to be reliably avoided during production, transport and storage. Inevitable voltages must be discharged in a controlled manner. Our certified ESD consultants gladly assist you with the development and implementation of ESD protection concepts.

Electrostatic discharge of a printed circuit board (PCB)

How does ESD protection work?

ESD protection starts with a sensitivity analysis of your products. The results give information about which ESD protection measures are required for your individual use case. As a fundamental concept, insulators must be avoided at your production sites (insulators are materials, which barely carry electricity and can easily be charged). Additionally, inevitable voltages need to be discharged in a controlled manner. Thereby, our ESD consultants focus on the following categories:

- People and clothing

- Floors and workstations

- Packaging systems and materials

- Machinery and tools

We will summarise our suggested ESD protection measures in your individual ESD manual (“ESD control program”) and help you with its implementation. We also offer employee training and long-term support as external ESD coordinators.

Focus on your core competencies and let us take care of your ESD protection!

Smart products are trending. Suddenly, manufacturers with little know-how about electrical engineering are required to integrate controllers or sensors, and especially ESD protection becomes a major challenge. That is why we gladly support you as external ESD coordinators while you can focus on your core competencies.

Frequently asked questions

- Removal of adhesive tapes

- Cleaning of components with pressurised air

- Rubbing different materials against each other, e. g. when transferring bulk material or liquids

- etc.

- Prevention of insulators (materials that hardly carry electric currents and, thus, can easily be charged)

- Controlled discharge of unavoidable charges

- ESD protection floors

- ESD protection clothing

- Earthing straps

- ESD protection furniture

- Suitable transport containers