MetaScope 5 Coating Thickness Gauge

Coulometric coating thickness measurement for galvanised copper wires

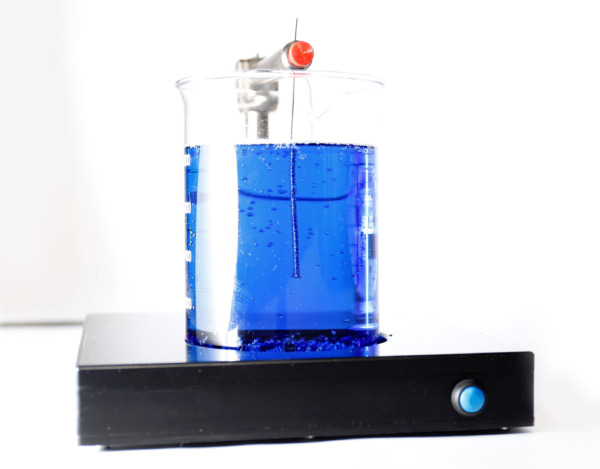

Description of the film thickness gauge

MetaScope 5 is a state-of-the-art coating thickness gauge. It can measure the thickness of tin, nickel and silver layers of galvanised copper wires. MetaScope 5 uses coulometric coating thickness measurement in accordance with EN ISO 2177.

As a preparation, the sample wire is cut to a specified length. It is then attached to the sample holder and, thereby, contacted to the measuring electronics. Next, a specified length of the sample is immersed into an electrolyte fluid and the inspection is started. During measurement, the galvanic layer is detached from the sample while the gauge analyses the amount of electricity required for this task. With the results, the film thickness gauge can calculate and display the coating thickness in µ-inch (or µm) and g/kg.

An alternative sample holder for very thin wires comes included with the plating thickness gauge.

Features

Plating Thickness Measurement Device

| Dimensions | W 375 mm x D 175 mm x H 85 mm |

| Weight | 3.5 kg |

| Operating temperature | 15 °C – 35 °C |

| Power supply | 100 – 240 V, 50 – 60 Hz, 75 W |

| Display | 7-inch capacitive-touch display, 800 x 480 pixels, colour |

| Connections | Power cord M12 connector to sample holder USB socket type A |

| Measurement range layer | 0.2 μm – 30 μm |

| Wire diameter range | 0.05 mm – 2.5 mm |

Sample holder

| Dimensions | W 230 mm x D 220 mm x H 330 mm |

| Weight | 2.3 kg |

| Base material | PVC, black |

| Holder material | Brass, nickel-plated |

| Stir function | Stepper motor in the base with a rod magnet |

| Connections | M12 socket with 1 m cable to the film thickness gauge |

| Beaker max. diameter | 107 mm |

| Beaker max. height | 150 mm |

| Beaker max. volume | 1,000 ml |

Configuration

Product types

| Name | Description |

| MetaScope 5 | Coulometric plating thickness gauge in accordance with EN ISO 2177, including sample holders |

Service for our plating thickness gauge

Related to our MetaScope 5 coating thickness gauge, we offer the following services:

- Factory calibration (recommended every 12 months)

- Integration of external database systems (such as MySQL) for storage of coating thickness measurement results

We are looking forward to your contact enquiry!