Test Fixture Design

Customer-specific test adapter design solutions

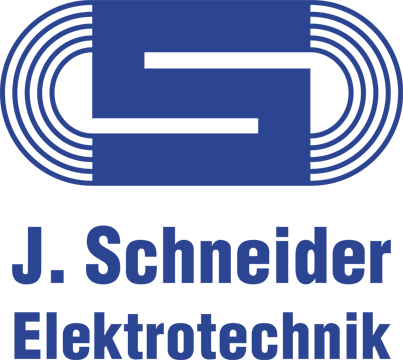

Our well-experienced test fixture design team offers the customisation of standard adapter kits as well as individual solutions. Since 2022, we primarily source INGUN components. But if desired, we also use products from other well-known manufacturers.

Experience with all types of devices under test (DUTs)

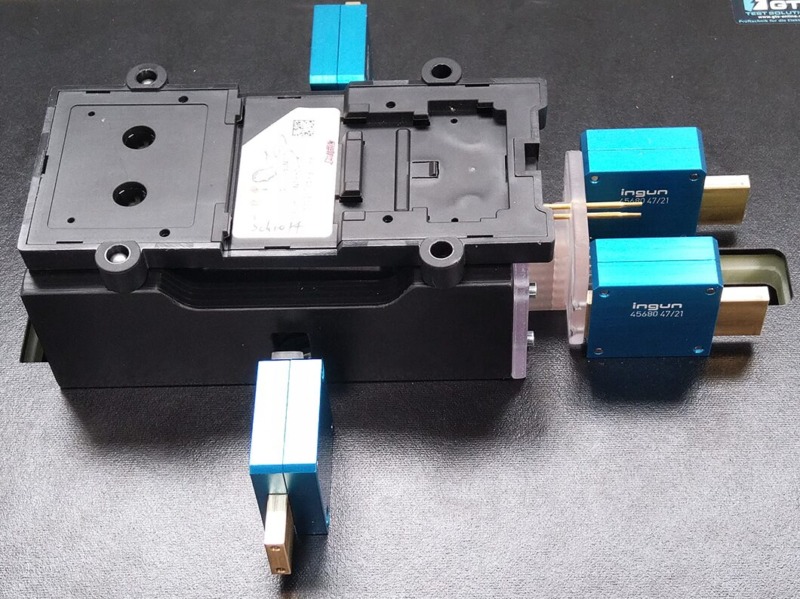

Our engineers have longstanding and cross-industry experience when it comes to contacting printed circuit boards (PCBs), electronic modules or devices. We successfully worked with exceptional formats as well as products that are very hard to contact. Bases on your product samples and 3D data, we handle the entire design and manufacturing process of your test fixture. Of course, we will optimise your test adapter for a reliable and efficient testing procedure.

High-quality products for every requirement level

All our test fixtures are designed for the high demands of industrial applications. Thereby, we offer suitable solutions for every requirement level: from the cost-efficient test adapter for small-batch production to the highly robust solution for mass production.

Thanks to our partnership with INGUN, our test fixture designers can rely on a wide range of standardised test adapter kits for various product sizes and with numerous expansion possibilities. For more complex customisation requirements or custom solutions, we look forward to receiving your contact inquiry!

Test fixture design for automated production lines

Upon request, the insertion and removal of your product can be automated. We support various handling systems, making our custom test adapters easy to be integrated into automated production lines.

The stress-strain analysis can determine the mechanical effects your device is exposed to when inserted into the test fixture. The results allow us to identify potential overstraining and to rectify it. Consequently, your products are better protected against failure in their future service life.

Besides INGUN, we also design test adapters from other well-known manufacturers upon request, including ATX, Equip-Test or GPS-Prüftechnik. We source original components ensuring original manufacturer quality.

Typical procedure for a test fixture design project

1. Requirements engineering

We discuss and analyse the test requirements of your product.

2. Conceptual design

Our engineers develop an optimal test adapter design for your requirements.

3. Presentation and approval

We present our concept and fine-tune it together with you.

4. Prototype construction

We construct a prototype of your test fixture and wait for your final approval.

5. Procurement

We procure required components and plan our production capacities.

6. Production and delivery

We produce the ordered amount of test adapters and deliver them.

Frequently asked questions about test adapter design

- CNC processing of adapter plates

- Installation of quick clamps according to your specifications

- Insertion of sleeves and pogo pins

- Pogo pins on multiple layers

- Installation of rigid or spring-loaded positioning pins

- Installation of hold-down pins

- Contacting connectors

- Installation of components (e. g. colour sensors, scanners, DIN rails, switches) and wiring

- Installation of screening surfaces

- Protective enclosure against dangerous voltages/discharges

- Protective enclosure against environmental light