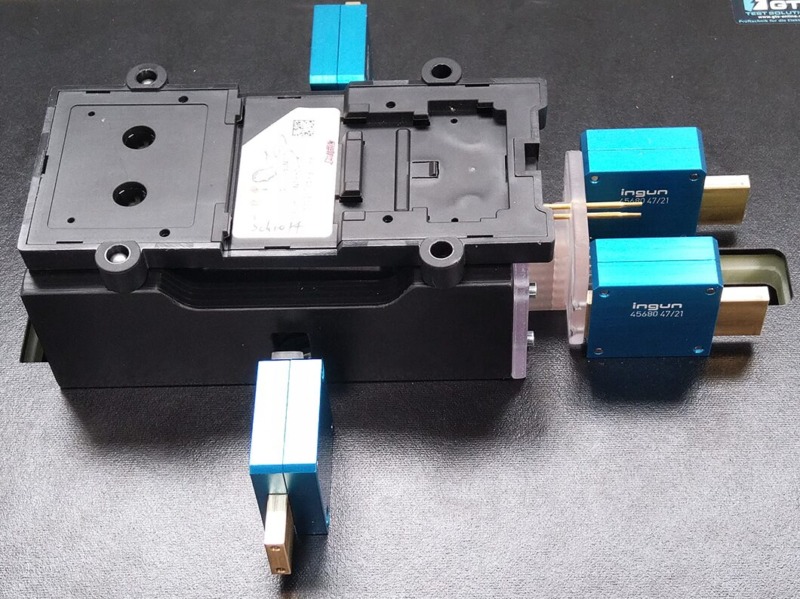

Experience with all types of devices under test (DUTs)

Our engineers have longstanding and cross-industry experience when it comes to contacting printed circuit boards (PCBs), electronic modules or devices. We successfully worked with exceptional formats as well as products that are very hard to contact. Bases on your product samples and 3D data, we handle the entire design and manufacturing process of your test fixture. Of course, we will optimise your test fixture for a reliable and efficient testing procedure.

Results in original manufacturer quality

We are happy to advise you on third-party test fixtures and find a suitable solution for your application scenario. When customising test fixtures from brands like ATX, Equip-Test, GPS-Prüftechnik or INGUN, we source original components. This allows us to ensure original manufacturer quality standards.

Test fixtures for automated production lines

Upon request, the insertion and removal of your product can be automated. We support various handling systems, making our custom test fixtures easy to be integrated into automated production lines.

The stress-strain analysis can determine the mechanical effects your device is exposed to when inserted into the test fixture. The results allow us to identify potential overstraining and to rectify it. Consequently, your products are better protected against failure in their future service life.

Typical procedure of a test fixture customisation project

1. Requirements engineering

We discuss and analyse the test requirements of your DUT as well as your wishes concerning third-party products.

2. Conceptual design

If not done so far, we will choose the optimal third-party hardware for your scenario.

3. Presentation and approval

We present our concept and fine-tune it together with you.

4. Prototype construction

We construct a prototype of your test fixture and wait for your final approval.

5. Procurement

We procure required original components and plan our production capacities for your test fixture customisation.

6. Production and delivery

We produce the ordered amount of test fixtures and deliver them.